Cart

0

-

Your shopping cart is empty!

Gray EPDM rubber cushion ring 205x180

Brand: Thái Dương Rubber

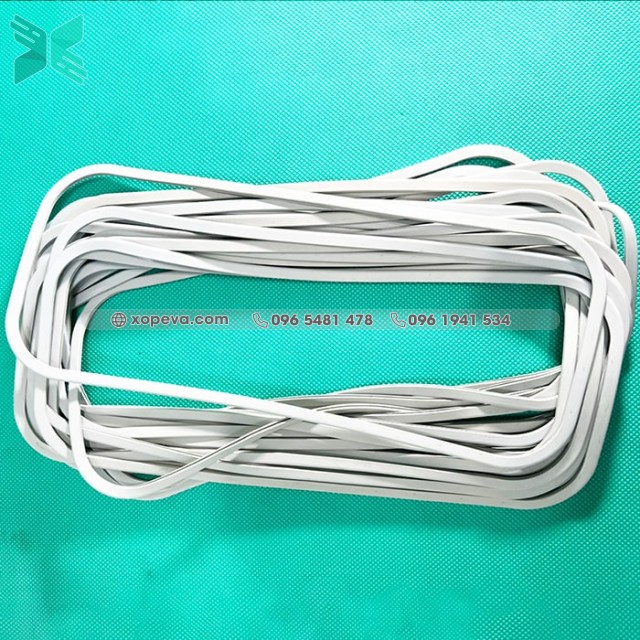

White T-Shaped Silicone GasketThe white T-shaped silicone gasket is a crucial component in various industrial and household applications. With flexibi..

Brand: Thái Dương Rubber

Silicone Thermal Interface Pad A silicone thermal interface pad is a specialized product made from silicone, a type of synthetic rubber known for..

(1)