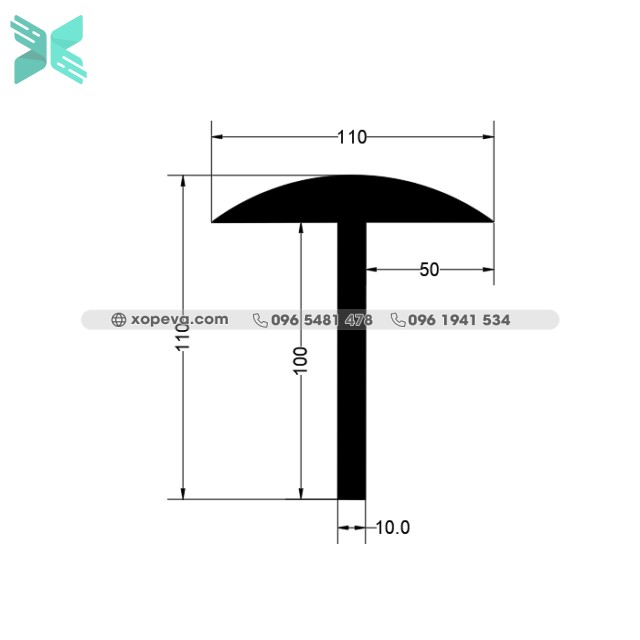

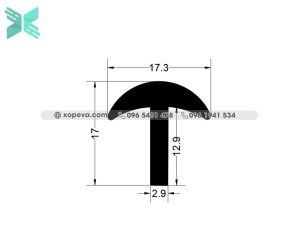

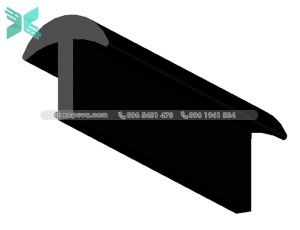

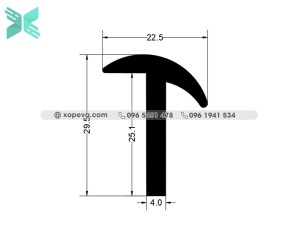

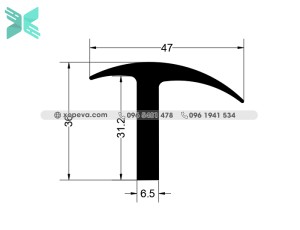

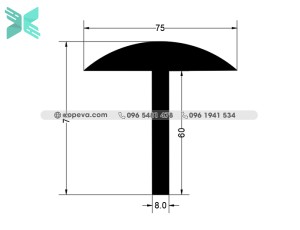

T-shaped rubber extrusions are rubber products with a T-shaped cross-section, produced by hot or cold extrusion processes from synthetic or natural rubber materials. This is a product with many features and benefits, including:

- High durability: T-shaped rubber extrusions are made from high-quality rubber materials, providing good durability and elasticity. Therefore, it is often used in applications that require high strength and resistance to wear, impact, or strong forces.

- Weather resistance: T-shaped rubber extrusions have good weather resistance, so they are not affected by weather conditions such as sun, rain, or wind. This makes them suitable for outdoor applications or in harsh environments.

- Insulation: T-shaped rubber extrusions have good insulation properties, so they are often used in electronic or refrigeration applications that require high insulation.

- Oil and chemical resistance: T-shaped rubber extrusions also have good resistance to oil and chemicals, so they are often used in applications related to grease or chemicals.

- Easy processing and installation: T-shaped rubber extrusions have a simple shape and standard size, making them easy to process and install in various applications.

In summary, T-shaped rubber extrusions are products with many features and benefits, making them widely used in various industries in the rubber field.