EPDM rubber is a widely used synthetic elastomer that offers excellent properties and versatility for various industrial applications. The acronym EPDM stands for Ethylene Propylene Diene Monomer, which refers to the chemical compounds used in its production.

EPDM rubber is known for its excellent resistance to heat, weathering, ozone, and UV radiation, making it a popular material choice for outdoor applications such as roofing, sealing, and automotive components. The material's excellent thermal stability allows it to perform well in a wide temperature range, from -50°C to 150°C.

In addition to its excellent weatherability, EPDM rubber also offers good chemical resistance to acids, alkalis, and polar solvents, making it a suitable material for gaskets, seals, and hoses in various industrial settings. Its high elasticity and resistance to deformation make it an ideal material for vibration dampening and impact resistance.

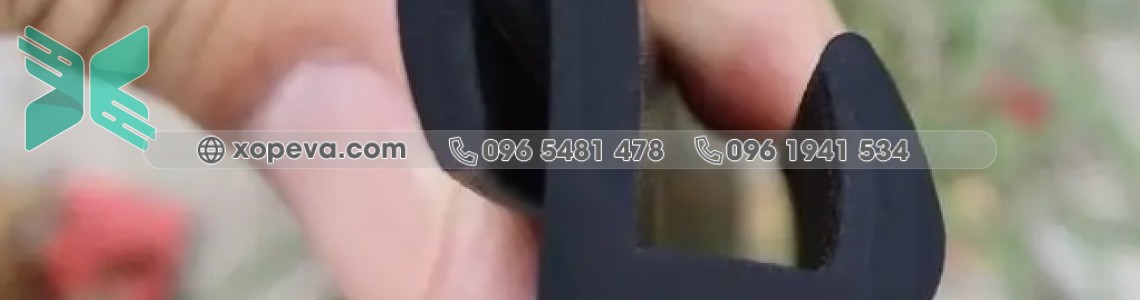

EPDM rubber can be formulated to have various physical properties, including hardness, modulus, and compression set, making it a versatile material that can be tailored to specific application requirements. The material can also be processed using various methods, including extrusion, molding, and calendering, allowing for the production of a wide range of products.

Overall, EPDM rubber offers a combination of excellent properties and versatility that makes it a popular choice for various industrial applications. Its resistance to weathering, UV radiation, and chemicals, coupled with its high elasticity and thermal stability, make it an ideal material for outdoor applications where durability and reliability are critical

Leave a Comment