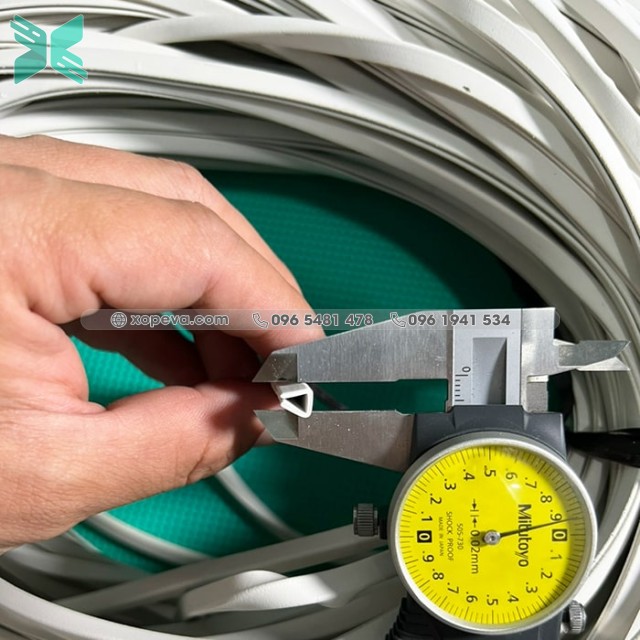

| Material: | EPDM Rubber |

| Size: | 6mm x 6mm x 1mm |

| Hardness (Shore A): | 50-75° |

| Minimum length: | 50m |

| Full coil length: | 100m |

| Colour: | White |

| Estimated delivery: | 6 to 8 working days |

White U-shaped rubber seals

White U-shaped rubber seals are a type of rubber seal with a U-shaped design and made from white rubber. They are a versatile rubber seal used in various applications. Here are some advantages and common applications of white U-shaped rubber seals:

Advantages:

1. Thermal and Sound Insulation: White U-shaped rubber seals have excellent thermal insulation properties, preventing heat and sound transmission between sealed surfaces. This enhances thermal insulation efficiency and reduces noise in seal applications.

2. Resilience and High Durability: White U-shaped rubber seals exhibit good resilience, making them easily stretch and regain their original shape after experiencing pressure or deformation. They also have high durability, allowing them to withstand pressure and harsh environments without damage.

3. Chemical Resistance and Oxidation Resistance: White U-shaped rubber seals often have resistance to chemicals and oxidation. This makes them suitable for applications in the chemical and petroleum industries, where contact with chemicals is unavoidable.

4. Sealing and Water Resistance: With its U-shaped design, this rubber seal can create a tight gap between surfaces, preventing water and liquids from entering the interior space. This makes white U-shaped rubber seals a good choice for applications requiring sealing and water resistance.

Applications:

1. Automotive Industry: White U-shaped rubber seals are widely used in automobile manufacturing and assembly to provide sealing and noise reduction between connected surfaces such as doors, hoods, trunk lids, etc.

2. Electronics Industry: This rubber seal can be used in electronic devices for insulation and water resistance.

3. Oil and Gas Industry: White U-shaped rubber seals with chemical resistance and heat resistance are utilized in oil and gas applications, such as oil pipelines, valves, compressors, etc.

4. Energy Industry: White U-shaped rubber seals can be employed in renewable energy devices, such as solar panels or batteries.

5. Medical Industry: This rubber seal can be used in medical devices such as testing machines, acupuncture devices, etc.

These are some details about white U-shaped rubber seals, including their advantages and common applications. The advantages and applications make white U-shaped rubber seals an important material in various industries.