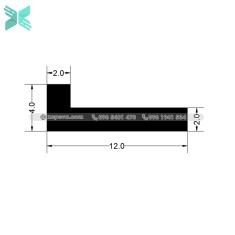

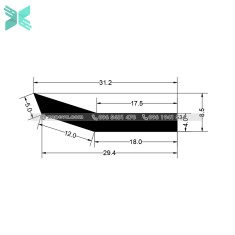

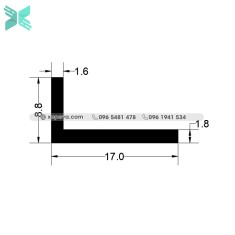

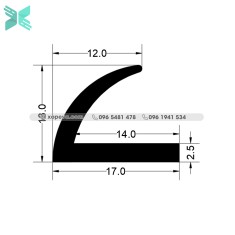

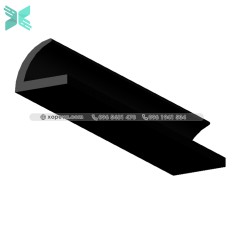

Rubber L-shaped gasket is a type of rubber accessory used to create a tight seal between two surfaces. L-shaped rubber gaskets are commonly used in applications related to machinery and mechanical equipment, especially in industrial applications. With flexibility and high durability, L-shaped rubber gaskets are widely used in industries, including electronics and healthcare.

Characteristics of L-shaped rubber gaskets:

L-shaped rubber gaskets are made from high-quality synthetic rubber material, with high durability and the ability to withstand environmental impacts. In addition, L-shaped rubber gaskets also have the characteristics of being soft, elastic, and flexible, allowing it to meet the tight sealing requirements of different applications.

Some applications of L-shaped rubber gaskets:

L-shaped rubber gaskets are used in many different applications in many industrial fields. Here are some common applications of L-shaped rubber gaskets:

• In the automotive and motorcycle manufacturing industry: L-shaped rubber gaskets are used to create a tight seal between the surfaces of the components of cars and motorcycles.

• In the machinery and mechanical equipment manufacturing industry: L-shaped rubber gaskets are used to create a tight seal between the surfaces of machinery and mechanical equipment components.

• In the electronics industry: L-shaped rubber gaskets are used to create a tight seal between the surfaces of electronic devices, especially in applications related to moisture and dust.

• In the healthcare industry: L-shaped rubber gaskets are used to create a tight seal between the surfaces of healthcare devices, especially in applications related to liquids and gases.

Benefits of L-shaped rubber gaskets:

L-shaped rubber gaskets have many benefits for their applications, including:

• Creating a tight seal: L-shaped rubber gaskets are used to create a tight seal between two surfaces. This helps prevent the escape of vapor, liquid, or gas through the gaps between the surfaces.

• Increasing durability for machinery components: L-shaped rubber gaskets have good elasticity and flexibility. When used to seal machinery components, it can help increase their durability by minimizing vibration, avoiding damage to other components, and increasing the life of the equipment.

• Adjusting surface discrepancies: When there is a discrepancy between two surfaces, L-shaped rubber gaskets can be used to adjust and flatten these surfaces. This helps increase the accuracy of the components and reduce surface damage.

• Resistant to environmental impacts: L-shaped rubber gaskets are made from high-quality synthetic rubber materials that have high durability and can withstand impacts from the surrounding environment, including temperature, chemicals, and pressure.

• Meets various requirements: With flexibility and high durability, L-shaped rubber gaskets can meet various requirements in different applications, including in the electronics and medical industries.

Summary:

L-shaped rubber gaskets are an important rubber accessory used to create a tight seal between surfaces in many different industrial applications. L-shaped rubber gaskets are flexible and highly durable, can meet various requirements, and have many benefits for their applications, including creating a tight seal, increasing the durability of machine parts, adjusting surface deviations, resisting the impacts of the surrounding environment, and meeting various requirements in industrial applications. L-shaped rubber gaskets are made from high-quality synthetic rubber materials that have high durability and can withstand impacts from the surrounding environment, including temperature, chemicals, and pressure. With flexibility and high durability, L-shaped rubber gaskets are an important accessory in the industry and have many applications in different fields, including the electronics and medical industries